TECHNOLOGIES / SOIL MIXING

A PROVEN SOLUTION FOR COMPLEX CONTAMINATED SITES.

ISOTEC provides soil mixing expertise and turn-key environmental remediation services to treat complex sites with high contaminant concentrations using oxidants (ISCO), reductants (ISCR) and metal stabilization reagents. When applied properly, soil mixing can effectively homogenize site soil and uniformly distribute reagents to targeted treatment zones, despite heterogeneous hydraulically conductive media. Additionally, there are no reagent volume limitations, so predetermined dosing rates may be applied in one pass. Reagent delivery with soil mixing has proven extremely effective in reaching treatment targets, which has allowed us to develop a high level of confidence in this approach.

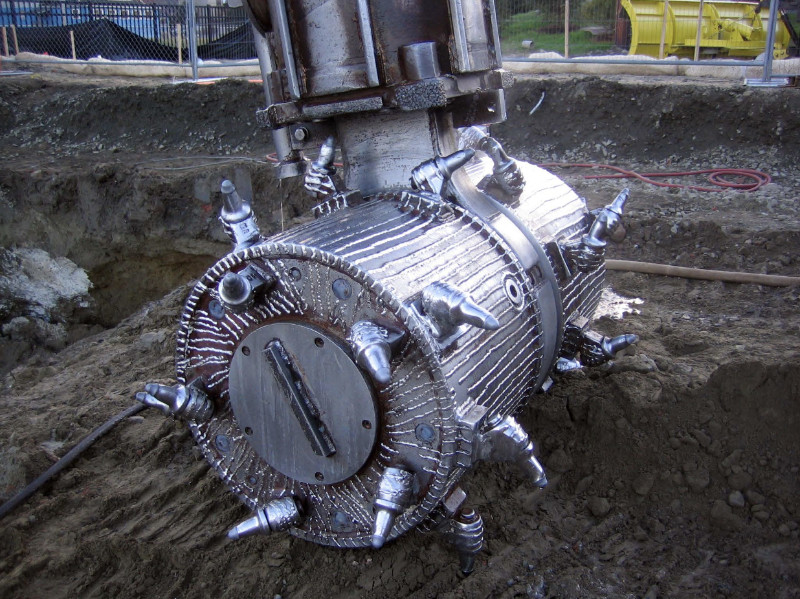

ISOTEC’s soil mixing options utilize multiple approaches, including bucket mixing, blending heads and state-of-the-art mixing tools designed to ensure full contact with the impacted media. Typically, the target area is divided into treatment cells (i.e. 10 ft x 10 ft) each receiving a predetermined volume of reagent introduced through the mixing tool head attachment (if liquids are utilized) or slowly applied to the treatment cell (if solids are utilized). If desired, the mixing tool operator can be guided by an on-board GPS system to ensure precise vertical plunges incorporate chemical dosages that can vary from one treatment cell to the next. Reagent dosages are typically determined through bench-scale treatability studies prior to field mobilization.

- In-situ chemical oxidation (ISCO) using soil mixing/blending involves the application of several chemical oxidants, alone or in conjunction, including sodium hydroxide activated sodium persulfate (B-ASP), hydrated lime activated sodium persulfate (L-ASP), modified Fenton’s reagent (MFR), MFR activated sodium persulfate (M-ASP), and permanganates. Reagents are directly blended into and/or around areas of known contamination in the subsurface to treat COCs in-situ.

- In-situ solidification (ISS) using soil mixing/blending involves the application of binding agents, typically Portland cement, and common additives such as fly ash, granulated blast furnace slag, hydrated lime, bentonite, and Organoclay®. Reagents are hydrated via a road portable additive mixing and grout pumping system and pumped to the head of the mixing tool.

- Soil stabilization using soil mixing/blending involves the application of metal stabilizers such as phosphates, sulfide reagents and iron rich clays for immobilization of hazardous heavy metals (e.g. lead, chromium, copper, cadmium).

All soil mixing/blending projects follow standard industry guidelines with respect to proper shoring and benching techniques, excavation, staging of excavated soils, backfilling and compaction procedures. Dust control and odor control are maintained and fuel-efficient equipment is utilized.